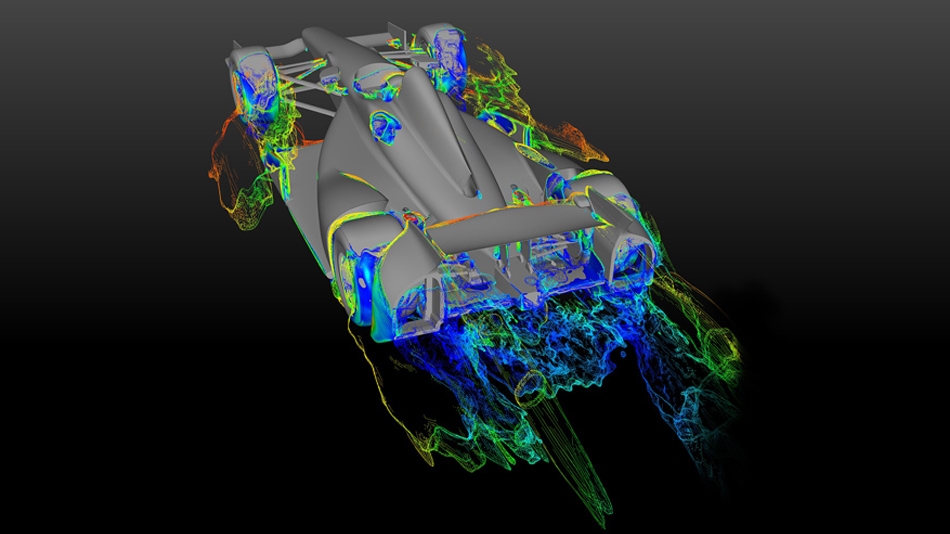

Mechanical and Composite Design

Our clients have access to Wirth Research’s proven, race winning, whole vehicle or component-level mechanical and composite design capability. The company has extensive experience in the design of composite monocoque structures, composite crash structures, complete transmission systems, engine integration, suspension design and advanced composite bodywork engineering. Wirth Research’s capabilities include a substantial simulation and Finite Element (FE) stress analysis function, with the ability to test and correlate new components or assemblies using an extensive range of in-house rig testing facilities.