Change is in the Air

Pushing the boundaries in aerodynamic and thermodynamic design

About WIRTH

Our Mission

We believe life can be more enjoyable and more sustainable through our technologies. We are able to make buildings better to live, work and shop in; to make vehicles more energy-efficient; and do all of this while providing our clients with a compelling return on their investment.

We’d love to hear about your energy consumption and ESG issues, particularly those linked to air or thermal inefficiencies, where our world-leading knowledge and application of Computational Fluid Dynamics (CFD) allows us to see what others can’t.

WHY WORK WITH US?

Engineering without limits

Wirth is a multi-award winning supplier of high-tech, innovative, energy-saving solutions to the retail and commercial buildings sectors, and a world-leader in Computational Fluid Dynamics (CFD). We provide our clients with high quality and proven Products & Services, delivered quickly and reliably. We solve issues as they arise without compromising integrity or customer vision.

Testimonials

What our

clients say

We very much enjoy Wirth's collaborative approach to solving technical challenges and their ability to communicate complexity in plain English"

PORTFOLIO

our Projects

We specialise in delivering sustainability and efficiency through aerodynamics and creative design. Our focus is on delivering technology that allows a sustainable future without the need for austerity. Wirth brings to market an expanding suite of patented, energy-saving technologies, which offer tangible benefits to the customer and exceptional ROIs to the companies deploying them. Reducing energy consumption and reducing CO2 emissions doesn’t necessitate compromise.

John Lewis Partnership

WAITROSE

85 Gracechurch Street

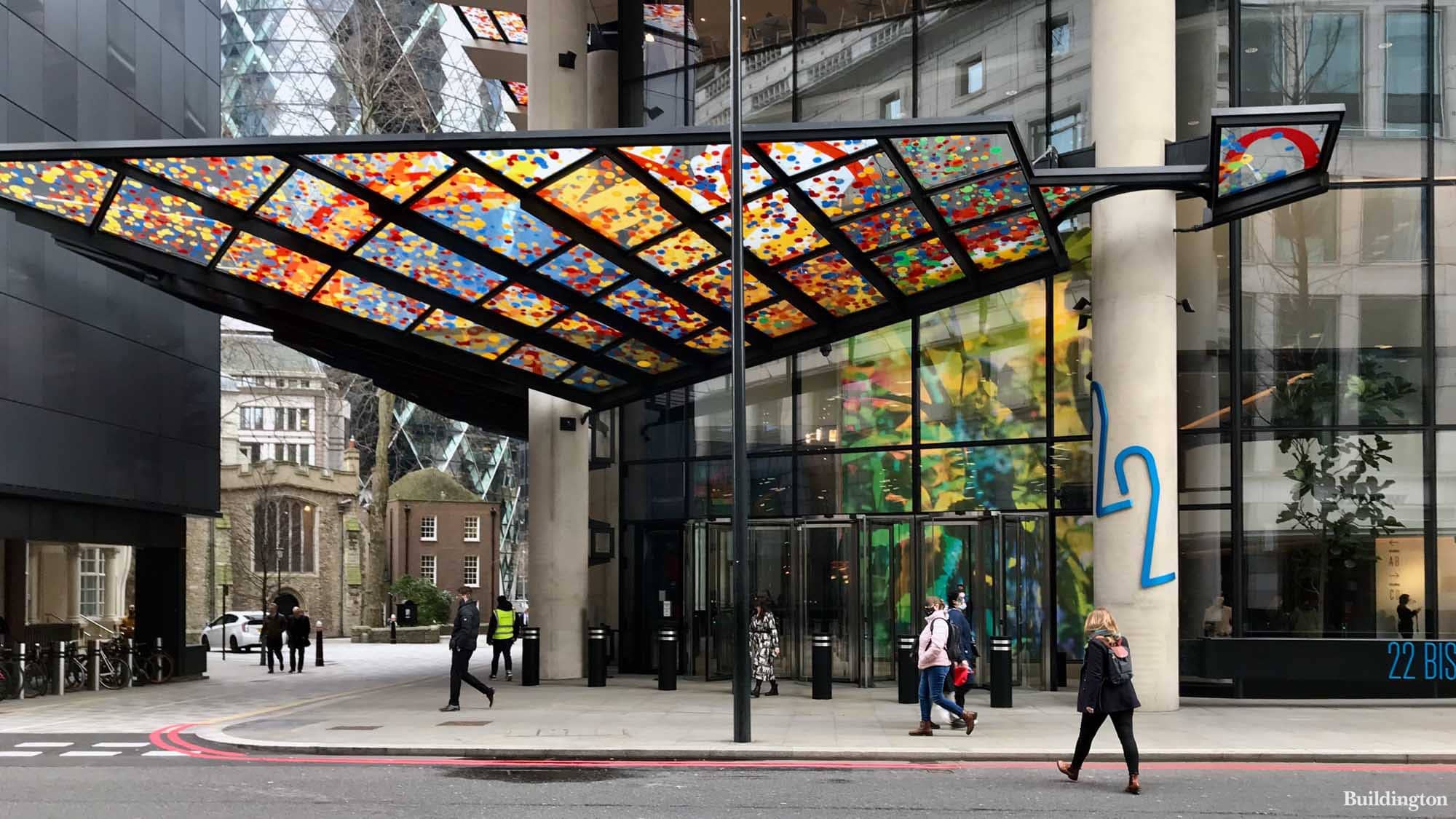

22 Bishopsgate

Charles Tyrwhitt

Royal Mail

LATEST NEWS

Recent Developments

Wirth Research Wins Cleantech Award at National Sustainability Awards 2025

Nick Wirth Shortlisted for IET Achievement Medal Award 2025

Wirth surpasses 100 granted patents

Nick Wirth Champions Air Flow Design for Climate Resilience in Earth.org Feature

subscribe

join our MAILING LIST

Good news & event details as well straight to your incoming mail!

Let’s Get in Touch

Contact details

Phone: +44 (0)1869 355260

E-mail: info@wirthresearch.com

Address: The Eco Business Centre

Charlotte Avenue

Bicester

Oxfordshire

OX27 8BL

United Kingdom